BlazeMaster® CPVC is the most specified non-metallic fire sprinkler piping system in the world. It is specially engineered and approved for all light hazard applications, as defined by AS 2118.1 (Australia), NZS 4541 (New Zealand) and the American approvals NFPA 13/13R/13D.

Building owners and contractors specify BlazeMaster fire protection systems because they:

- Install quickly, quietly and securely.

- Won’t sustain a flame.

- Inherently resist pitting and corrosion.

- Resist microbiologically influenced corrosion (MIC).

- Are lightweight and durable.

- Limit smoke generation.

- Require less space for installation.

Review the BlazeMaster Fire Protection Systems’ international listings and approvals below for third-party verification of our fire sprinkler system’s performance and reliability.

Where Can BlazeMaster® Fire Protection Systems Be Used?

BlazeMaster CPVC pipe and fittings are listed by Underwriters Laboratories (UL), FM Approvals (FM), and NSF International. Examples of areas where BlazeMaster is approved for use:

- Light hazard occupancies

as defined in AS 2118.1 Automatic Fire Sprinkler Systems General Systems (Australia), NZS 4541 Automatic Fire Sprinkler Systems (New Zealand) and the American Standard for the installation of Sprinkler Systems NFPA 13.

- Ordinary hazard installations as defined in AS 2118.1 Automatic Fire Sprinkler Systems General Systems (Australia), NZS 4541 Automatic Fire Sprinkler Systems (New Zealand).

- Air plenums. For guidance, please contact technical support.

- From AS 2118.1 Appendix A: Below are examples of occupancies in which approved plastic pipe may be used:

- Light Hazard Occupancies

- Art galleries

- Baths (Saunas, Turkish)

- Boarding Houses

- Churches and chapels

- Computer server and communication equipment rooms smaller than 126m2

- Gymnasiums

- Hospitals, and residential care facilities

- Libraries (excluding stack room)

- Medical and dental consulting rooms

- Museums (low combustible loading)

- Offices

- Prisons

- Residential portions of buildings such as clubs, hotels, motels and apartment buildings

- Schools, colleges, universities (excluding chemical laboratories and library stack rooms)

- Sewage works

- Waterworks and pumping stations

- Ordinary Hazard 1 Occupancies (OH1)

- Clubs, hotels, motels excluding higher hazard areas such as public entertainment area, discos and gaming (excluding lower hazard areas such as residential accommodation or associated areas)

- Restaurants and cafes

- Abrasive wheel and powder manufacturing

- Aerated water manufacturing (not on brewery premisses)

- Cold glass processing, including mirror manufacture, stain glass assembly, double glazing fabrication, glaziers premises and fitting glass to metal window framers

- Dairy food processing (excluding packaging)

- Fibrous cement millboard manufacturing

- Galvanising work

- Ice factories

- Jewellery manufacturing and engraving

- Plant rooms (building services only)

- Plating

- Pre-cast concrete and brick manufacturing

- Salt manufacturing

- Stone working premises

- Light Hazard Occupancies

Note: For residential buildings containing not more than four stories, refer to As 2118.4

Note: For New Zealand LH and OH1 Occupancies, refer to NZS 4541

Temperature and Pressure Rating

BlazeMaster pipe and fittings, size 20 mm to 80 mm (3/4 in. to 3 in.) are rated for continuous service of 175 psi (1207 kPa) at 65°C (150°F). Their use is suitable for use in areas where ambient temperatures are within the range of 2°C to 65°C (25°F to 150°F).

BlazeMaster pipe and fittings can be used in installations below2°C (25°F) with compatible antifreeze.

In an area where the temperature will exceed 65°C (150°F) such as an attic, BlazeMaster CPVC can be installed if ventilation is provided or if insulation is used around the pipe to maintain a cooler environment.

The piping systems must be laid out to ensure the piping is not closely exposed to devices that generate heat in excess of 65°C (150°F) such as light fixtures and steam lines.

If the installation is in an area subject to freezing temperatures, the sprinkler system must be protected from freezing. A frozen system will not only be deactivated, but the pressures that may build up can cause the sprinkler heads to open or damage the pipes.

Product Ratings, Capabilities and Material Properties

Pipe Dimensions and Weights

BlazeMaster pipe is produced in SDR 13.5 dimensions. SDR, or standard dimensional ratio, means the pipe wall thickness is directly proportional to the outside diameter. This results in consistent pressure capabilities across all diameters.

The pipe is produced to the specifications of ASTM F442. Fittings are produced to ASTM F437, F438, or F439 specifications depending on the system size and configuration.

Physical and Thermal Properties

Hydraulic Design

C Factor

Hydraulic calculations for the sizing of BlazeMaster pipe and fittings is calculated using the Hazen-Williams C factor of 150. The piping maintains this C-factor throughout the life of the system.

Pipe Friction Loss

Pipe friction loss calculations are made according to NFPA 13 Section 23.4 (2016 Edition).

Fittings Friction Loss

Thermal Expansion and Contraction

BlazeMaster CPVC pipe, like all piping materials, expands and contracts with changes in temperature.

The coefficient of linear expansion is: 0.000061 cm / cm °C (0.0000340 inch/inch-°F) and linear expansion is the same for all pipe diameters.

For example, a 13.9°C (25°F) change in temperature will cause an expansion of 2.5 cm (1 inch) for a 30.5 m (100 foot) straight run of BlazeMaster pipe.

For most operating and installation conditions, expansion and contraction can be accommodated at changes in direction of the pipe run. However, in certain instances, expansion loops or offsets may be required when installing long, straight runs of pipe.

THE FORMULA TO CALCULATE THE AMOUNT OF THERMAL EXPANSION OR CONTRACTION IS

ΔL = 12 * E * L * ΔT

Where: e = 3.4 * 10-5 inch/inch-°F; L = Length of run in feet; ΔT = Temperature change °F;

ΔL = Change in length due to change in temperature

Thermal Expansion in Centimeters

Thermal Expansion in Inches

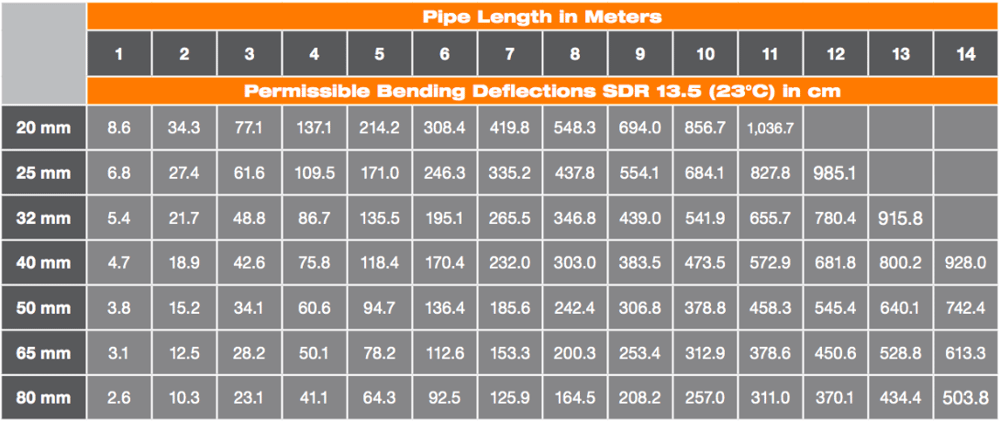

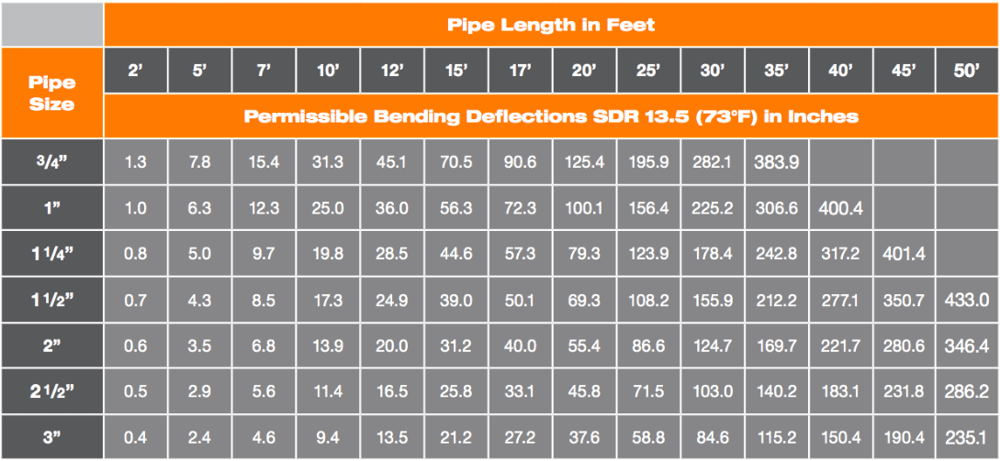

Pipe Deflection

BlazeMaster fire protection piping is inherently ductile, which allows it to deflect—within permissible limits—around or away from objects during installation.

This ductility allows for greater design freedom, reduce installation time and lower installed cost. The maximum installed deflections for BlazeMaster piping are as follows, in both feet and meters:

Specify BlazeMaster CPVC

To reach communities around the globe, we distribute widely through our network of partner manufacturers. They have a proven track record of producing the highest quality materials and are required to satisfy BlazeMasters’ Quality Assurance Program, which ensures you purchase the highest quality pipe and fittings available. Learn more about our partner manufacturers.

For specification support, or for questions about partner manufacturers in your area, our team of product and engineering specialists is available.